Understanding the Benefits of Conducting an Energy Audit

Outline:

– Energy Audits 101: What They Are and Why They Matter

– Turning Data into Efficiency: Methods and Measures

– Sustainability Outcomes Beyond kWh

– Energy and Cost Savings: From Estimates to Verified Results

– Getting Started: Choosing the Right Audit and Avoiding Pitfalls

Energy Audits 101: What They Are and Why They Matter

Think of an energy audit as a building’s checkup: a structured investigation that discovers where energy goes, why it is wasted, and how to capture practical savings. Auditors review utility bills, inspect equipment and the building envelope, and convert observations into a prioritized list of improvements. The goal is not to sell gadgets; it’s to diagnose the root causes of waste—oversized equipment, leaky ducts, drifting setpoints, poor schedules, or aging insulation—and translate them into actionable fixes. In most homes and commercial spaces, audits uncover a meaningful range of opportunities; industry surveys often report achievable reductions in energy use on the order of 10–30% when recommended measures are well implemented, though actual results vary by climate, occupancy, and starting condition.

Why this matters stretches across three pillars: efficiency, sustainability, and energy savings. Efficiency means doing the same (or more) with fewer kilowatt-hours or units of fuel, often by tuning operations, upgrading to high-performance components, and improving control strategies. Sustainability follows naturally: less energy use usually means fewer greenhouse gas emissions, especially in regions where electricity or heating fuels carry significant carbon intensity. Energy savings provide the financial motivation, improving operating margins in businesses and lowering monthly bills for households. The ripple effects can extend to comfort and resilience—quieter equipment, more even temperatures, and reduced strain on critical systems during peak demand.

An audit typically scales to the needs of the building. A basic walkthrough identifies obvious opportunities and “no-cost” or “low-cost” actions such as schedule fixes, thermostat corrections, or sealing visible air leaks. A more detailed diagnostic study collects interval data, models loads, tests ducts and envelopes, and evaluates the lifecycle economics of upgrades. At the high end, an investment-grade audit refines assumptions with measurements and market pricing to support capital planning. Across this spectrum, the output is a clear roadmap that tells you what to do first, what to bundle, and what performance you can reasonably expect based on measured data rather than guesswork.

Key takeaways include:

– Audits find both quick wins (controls, maintenance, setpoint discipline) and deeper retrofits (envelope improvements, right-sized equipment).

– Benefits reach beyond bills: better comfort, potentially improved indoor air quality, and longer equipment life due to reduced cycling and strain.

– Success depends on follow-through: a strong plan, responsible budgeting, and verification to ensure predicted savings translate into real outcomes.

Turning Data into Efficiency: Methods and Measures

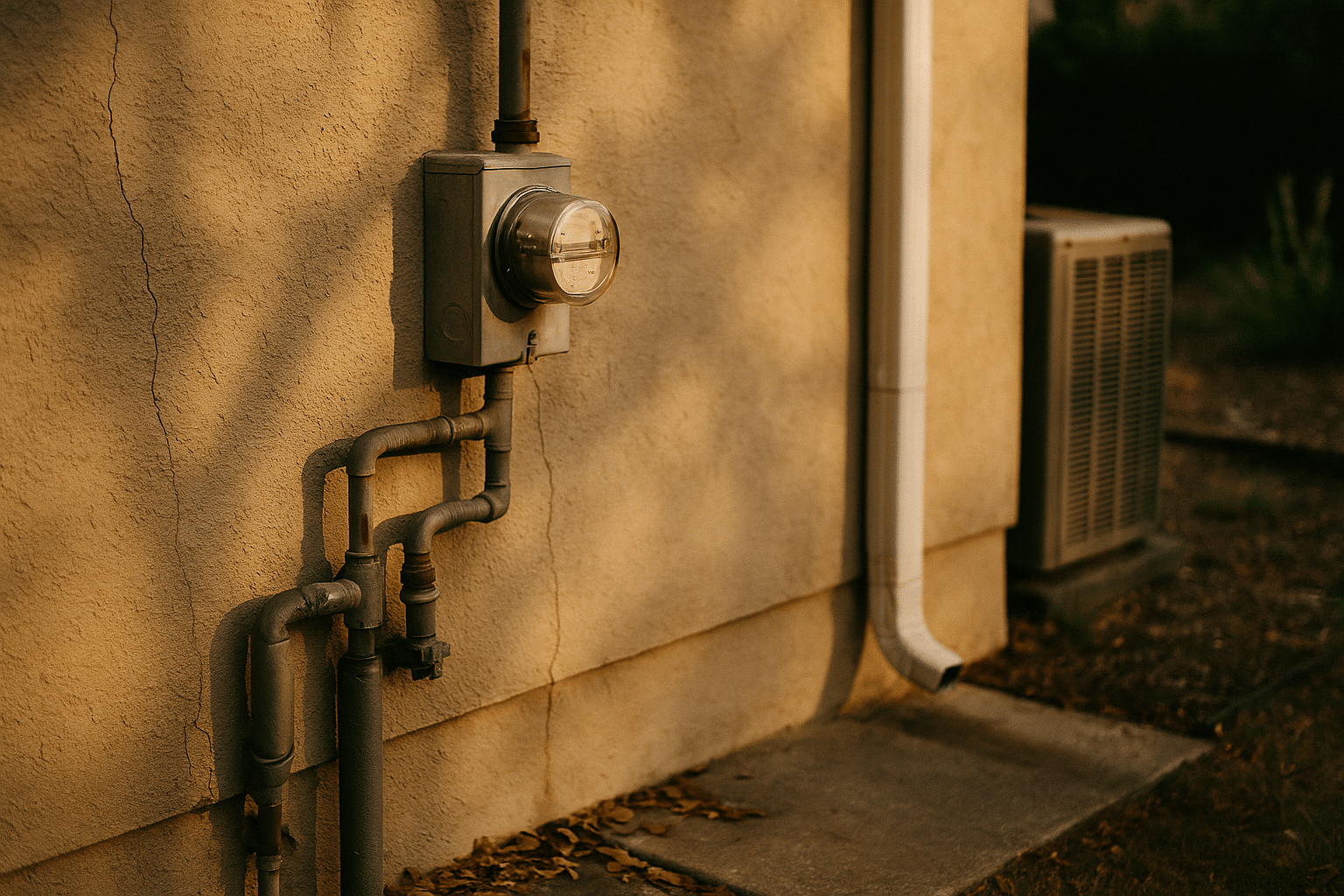

Audits turn scattered clues into actionable insights by following a disciplined methodology. It starts with data: at least 12 months of utility bills to understand seasonal patterns and base loads. With that, analysts often benchmark energy use against similar buildings, identify weather sensitivity using degree-day or temperature correlation, and isolate baseload consumption that persists even when a space is unoccupied or mild weather prevails. On-site, the process expands—infrared scans reveal insulation gaps, blower-door or duct tests quantify air leakage, and spot metering identifies plug loads that quietly sip energy all day.

The real magic lies in translating findings into measures. Consider a common pattern: a large, constant nighttime electrical load in an office. Investigation might trace it to server closets without schedule controls, vending machines with lights and compressors running 24/7, or ventilation fans left in hand mode. Solutions can be as simple as timer controls, advanced as occupancy-based ventilation strategies, or operational as updating standard operating procedures and training staff. Another example: short-cycling of oversized boilers or heat pumps; right-sizing, staging, or adding buffer tanks can reduce cycling losses, while modern controls can optimize run times and temperatures to match real demand.

Building envelope and lighting often yield accessible gains. Air sealing around penetrations, attic hatches, and rim joists reduces infiltration; adding insulation to attics or walls tightens the thermal boundary; and high-efficiency lighting with thoughtful controls curbs unnecessary burn hours. Yet auditors also look beyond “usual suspects.” They dissect domestic hot water systems, evaluate distribution losses in piping, and examine kitchen or process loads. In many facilities, control issues dominate: miscalibrated sensors, overrides that were never reset, and schedules that creep from occasional to permanent. Restoring intent—putting systems back on automatic with verified setpoints—can recover significant savings at modest cost.

To keep recommendations practical, measures are bundled. For example:

– Combine air sealing with ventilation upgrades to maintain healthy airflow while reducing drafts.

– Pair lighting upgrades with daylighting controls to capture both efficacy and behavioral savings.

– Coordinate equipment replacements with envelope improvements so that newly right-sized systems avoid the penalty of overcapacity.

Throughout, documentation matters. Good audits include a measure-by-measure description, estimated energy impact with transparent assumptions, simple financial metrics, and notes on operational impacts. This transparency helps owners compare options and avoid the common trap of chasing a shiny technology while overlooking a low-cost operational fix with bigger returns.

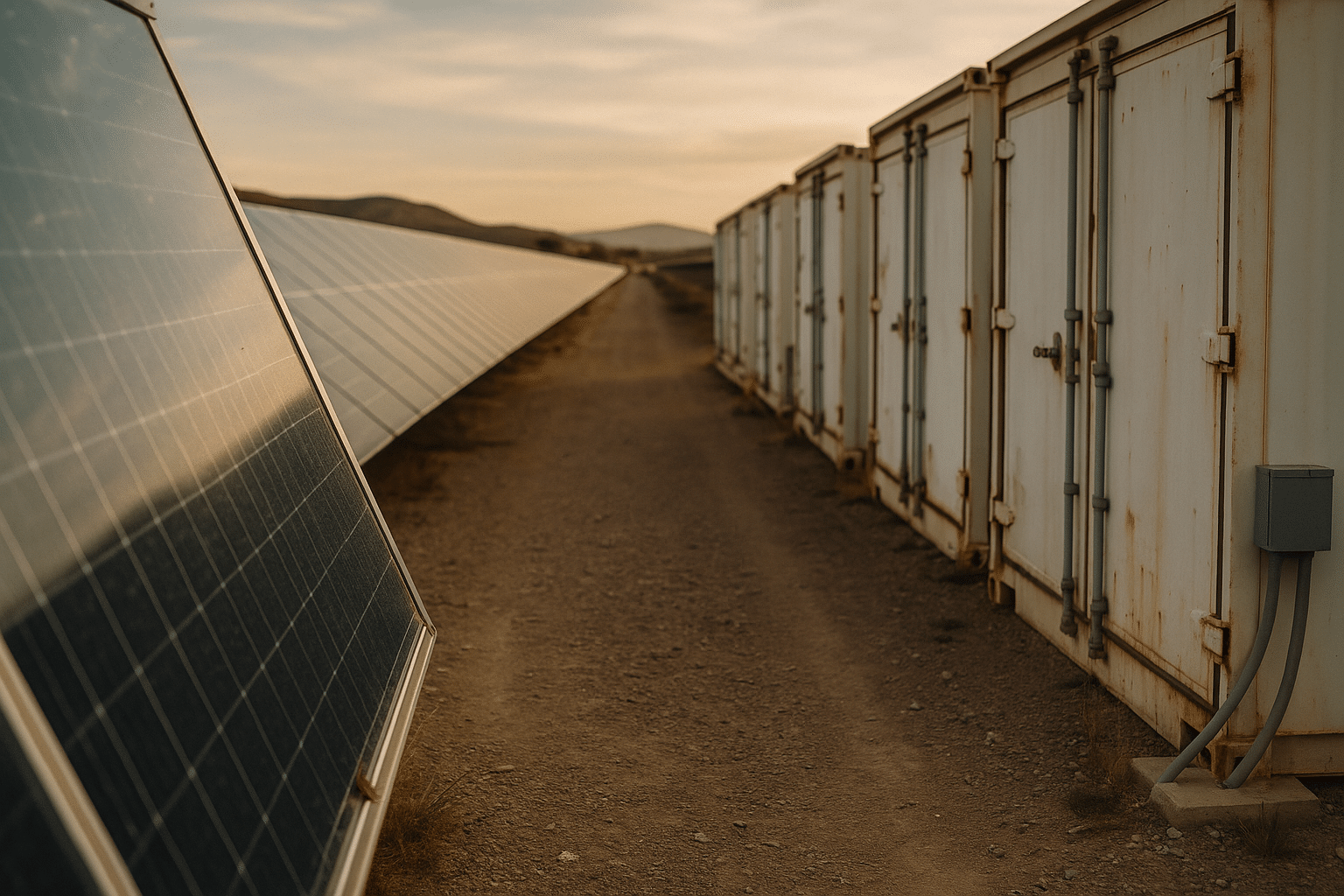

Sustainability Outcomes Beyond kWh

Energy is the headline, but sustainability is the broader story. Cutting consumption usually lowers emissions, and an audit helps quantify that link. Electricity’s carbon intensity varies significantly by region and over time; a rough illustrative range for grid electricity spans about 0.2 to 0.7 kilograms of CO₂ per kilowatt-hour, depending on local generation mix. That means an audited reduction of 20,000 kWh per year could translate to something like 4 to 14 metric tons of CO₂ avoided annually in many areas—substantial progress for a single building, especially when multiplied across a portfolio or community. For fuels like natural gas or heating oil, per-unit emissions are more stable, making calculations straightforward once usage cuts are estimated.

An audit can also surface sustainability wins not captured by a utility bill. Improving envelope tightness reduces drafts and hot/cold spots, which can enhance comfort and potentially reduce health complaints linked to poorly controlled humidity or temperature swings. Optimizing ventilation with demand-control strategies can help maintain indoor air quality while avoiding excess fan energy. In humid climates, better dehumidification strategies can slow mold growth risks; in dry regions, improving economizer operation can expand free cooling hours.

Water-related impacts deserve attention, too. Domestic hot water accounts for a notable share of energy in many homes and certain commercial facilities. Audits that identify pipe insulation gaps, excessive recirculation, or outdated fixtures may cut both water and energy use. In restaurants, hotels, and healthcare settings, targeting hot water systems and laundry operations can yield outsized sustainability benefits without compromising service quality. By extension, some audits evaluate refrigeration and food storage practices, which influence both energy and food waste—another sustainability intersection often overlooked.

Finally, there is the material side of sustainability. Replacing equipment has embodied impacts; stretching the life of existing assets through better maintenance and controls can be a responsible choice when performance permits. Conversely, when equipment is truly inefficient or nearing failure, planning a right-sized, higher-efficiency replacement avoids emergency purchases that lock in waste for another decade. The audit frames these trade-offs, helping decision-makers weigh operational savings, emissions reductions, comfort, resilience, and embodied impacts in a single, coherent plan.

In short, a strong audit turns sustainability from an abstract aspiration into a list of measurable actions:

– Quantify emissions impacts alongside energy and cost.

– Address comfort and indoor environmental quality, not only kilowatt-hours.

– Consider water, refrigeration, and process loads to capture non-obvious wins.

– Balance operational fixes with thoughtful, timed capital upgrades.

Energy and Cost Savings: From Estimates to Verified Results

Financial clarity is where audits earn enduring trust. The report should show, measure by measure, how energy and demand change, how that affects bills, and how costs and timelines stack up. Simple payback is common—project cost divided by annual savings—but owners increasingly prefer metrics that reflect time value, such as net present value and internal rate of return. To avoid overconfidence, assumptions must be explicit: operating hours, weather normalization, utility rates, and interactions between measures. For example, improving lighting efficacy reduces both lighting energy and cooling load, but may slightly increase heating needs in winter; ignoring such interactions can inflate savings.

Consider an illustrative scenario. A mid-size office spends 300,000 kWh per year on electricity at an average blended rate of $0.15 per kWh, for $45,000 in annual electricity charges. The audit identifies a package of measures—schedule optimization, ventilation control, plug-load management, and lighting upgrades—estimated to reduce consumption by 20%, or 60,000 kWh. That equates to about $9,000 in annual savings at the current rate. If implementation costs total $40,000, simple payback is roughly 4.4 years; depending on maintenance savings and comfort improvements (which can reduce churn or absenteeism), the true value can be higher than what utility-line items alone suggest.

Verification ties prediction to reality. After implementation, owners can meter specific systems, compare weather-normalized usage before and after, and track demand peaks to confirm that control strategies are working. Independent commissioning or periodic re-tuning helps keep performance from drifting. Many organizations adopt a “monitor, measure, manage” rhythm: monthly checks for anomalies, quarterly reviews of building automation trends, and annual mini-audits to refresh priorities. This light but steady cadence maintains momentum, ensuring that one-time savings persist over the long haul.

Funding often becomes the hinge between analysis and action. Options may include:

– Utility or municipal incentives that buy down project costs.

– On-bill repayment or low-interest loans that align payments with savings.

– Service contracts where providers are paid in part from realized savings, with careful attention to transparent baselines.

– Internal capital budgeting that prioritizes measures with strategic co-benefits such as resilience or comfort.

None of these require grand promises; they require careful scoping, clear documentation, and a willingness to validate results. When an audit places numbers on equal footing with operational realities, it becomes a reliable guide for both cautious and ambitious stakeholders.

Getting Started: Choosing the Right Audit and Avoiding Pitfalls

Embarking on an audit is simpler when you know the path. Begin by defining your scope: are you seeking quick wins, a capital plan for the next three to five years, or a portfolio strategy? From there, select the audit depth. A basic walkthrough highlights immediate, low-cost actions. A detailed diagnostic adds testing, modeling, and more refined economics. An investment-grade study validates assumptions with measurements and market quotes, suitable for board-level decisions. Whichever level you choose, clarity on goals and decision thresholds makes the process efficient and avoids rework.

Preparation accelerates value. Gather 12–24 months of utility bills, floor plans or sketches, equipment nameplate data, operating schedules, comfort complaints, and maintenance logs. If you have submeter or data-logger access, export interval data to reveal daily patterns. Appoint a point of contact who understands operations, and set up a short walk-through agenda that covers mechanical rooms, roof areas, representative spaces, and any known problem zones. During the visit, encourage a “why” mindset—why is this pump on at midnight, why is this thermostat always in override—so that recommendations target root causes, not symptoms.

Common pitfalls are surprisingly consistent:

– Treating controls as an afterthought; in many buildings, schedule and setpoint discipline deliver outsized savings.

– Chasing equipment swaps without addressing envelope or ventilation, which can shrink the equipment size and cost if done first.

– Underestimating commissioning; new equipment will not save energy if it is installed but not tuned.

– Ignoring occupant patterns; cleaning crews, late shifts, or seasonal events can reshape load profiles.

– Skipping verification; without post-implementation review, predicted savings can quietly erode.

Selecting a qualified professional helps. Look for documented experience with similar building types, sample reports that show transparent assumptions, and references that speak to follow-through. Ask how interactions between measures are handled, how uncertainties are expressed, and what support is provided during implementation and verification. Finally, plan for persistence: create a living list of measures, rank by impact and effort, assign responsibilities, and schedule re-tuning. An audit is not an endpoint; it’s the opening chapter of a building’s ongoing story of smarter operation, cleaner performance, and lower total cost.

Conclusion: A Practical Roadmap for Owners, Managers, and Households

An energy audit turns curiosity into clarity and intention into a step-by-step plan. For homeowners, it cuts bills and drafts while making rooms feel right; for facility managers, it aligns budgets, comfort, and risk management; for small businesses, it improves margins without compromising service. Start with the scope that matches your goals, implement the highest-value actions first, and verify the results so savings endure. With a measured approach, your building becomes leaner, cleaner, and more resilient—on your timeline and within your means.