Benefits of Regular Professional Duct Cleaning Services

Outline:

– The invisible highway: why ducts shape indoor air quality

– Ventilation fundamentals and how clean ducts preserve airflow

– HVAC efficiency, energy, and comfort gains from clear ductwork

– Health, cleanliness, and risk reduction: when cleaning matters most

– Conclusion and maintenance roadmap for homeowners and facility managers

Introduction:

Air quality, ventilation, and HVAC performance are three threads of the same fabric. The cleaner the pathways that deliver air, the steadier the airflow and the more consistent the comfort. Over time, dust, renovation debris, pest residue, and moisture can turn ductwork into a drag on the whole system. Regular professional duct cleaning, done with proper containment and filtration, helps restore design airflow, trim wasted energy, and reduce irritants that settle on surfaces and in lungs. This article unpacks how and why that routine service supports cleaner air, stronger ventilation, and longer equipment life.

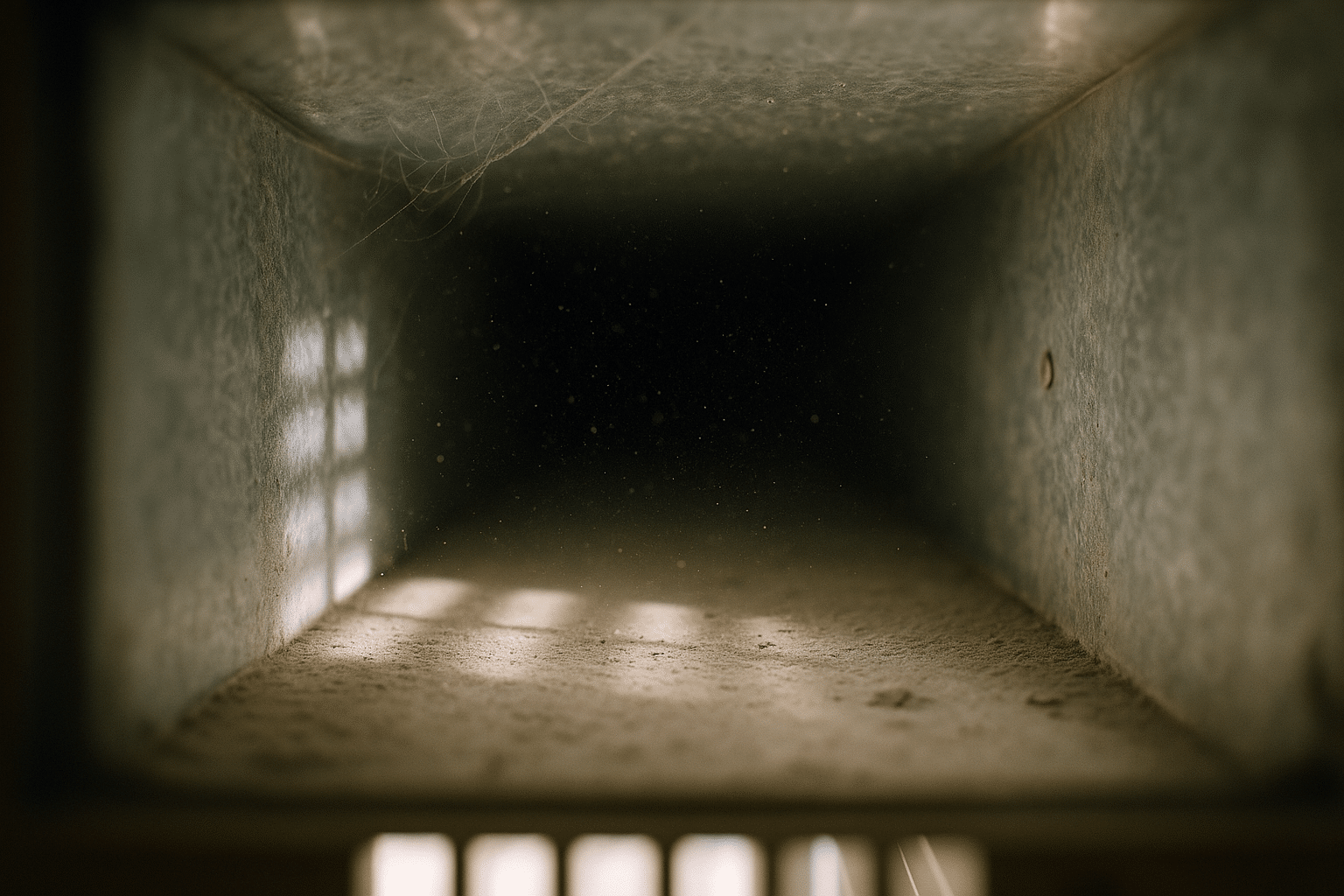

The invisible highway: why ducts shape indoor air quality

Every forced-air system relies on a hidden network of supply and return ducts—an invisible highway that moves air from room to room. When those passages accumulate dust and fibrous debris, the particles do not remain politely out of sight; they can be nudged forward whenever the fan starts, adding to the airborne load that occupants breathe and the dust that settles on desks, shelves, and vents. While filtration at the air handler captures a large share of particulate matter, buildup inside ducts can reintroduce contaminants downstream of the filter or release them during fan cycling and damper movement. The result is not only cosmetic dusting headaches but also a background haze of fine particles and fibers that can irritate sensitive occupants.

To understand the impact, consider how volume and speed amplify exposure. A typical residential system can move thousands of cubic feet of air each hour while running; even a thin layer of settled debris becomes meaningful when disturbed by that flow. Larger particles (think pet hair and crumbs) are obvious, but the real troublemakers often measure a fraction of the width of a human hair. These fine particles remain suspended longer and can travel into deeper parts of the respiratory tract. If a return duct draws from a basement workshop or a room where candles are frequently burned, the interior of that duct becomes a record of activity, collecting residues that later migrate throughout the home.

Professional duct cleaning addresses this reservoir effect. By placing the system under controlled negative pressure and agitating surfaces with specialized tools, a technician can remove accumulated dust and fragments that ordinary vacuuming at the grille cannot reach. Equally important is containment: high-efficiency filtration on the collection equipment prevents removed particles from re-entering the occupied space. A clean interior surface does not eliminate the need for good filtration and regular filter changes, but it reduces the baseline dust available to be recirculated and settles the ecosystem inside the ducts. That means fewer surprise plumes from registers, slower dust buildup on furnishings, and a more predictable starting point for improving indoor air quality with other strategies like source control and ventilation.

Signs that your ducts may be undermining air quality include:

– Visible puffs of dust when supply registers start up

– Dark streaks or fuzzy deposits around grilles and diffusers

– Musty or stale odors that linger after the system runs

– Uneven dust accumulation across rooms served by the same system

Ventilation fundamentals and how clean ducts preserve airflow

Ventilation is the steady exchange of indoor and outdoor air to dilute pollutants and control humidity. Whether a building uses a simple exhaust fan strategy, a dedicated outdoor air duct, or a fully balanced system, the goal is the same: deliver enough fresh air to occupied spaces while carrying away stale air. Ducts are the arteries and veins of this process. When they are constricted by debris, collapsed liners, or deposits at turning vanes, overall resistance to airflow rises. Fans must work harder to deliver the same volume, and in many cases they simply cannot, so effective ventilation rates fall below design targets. Clean ducts minimize friction losses, allowing actual delivery to track more closely with calculations on paper.

Small changes in friction can have outsized consequences, because fans operate along curves that describe the relationship between pressure and flow. Add resistance, and the flow shifts downward; remove resistance, and the flow shifts upward. In practice, a thin felt of dust inside a return trunk, lint lodged at a branch takeoff, or debris caught behind a register can be enough to change the distribution of air across rooms. Bedrooms at the end of long runs might receive less fresh air, while rooms near the air handler get more, yielding uneven ventilation. The building feels “stuffy” in some zones even while others are over-served, and humidity control becomes harder as stale, moist air lingers where circulation is weakest.

Professional cleaning helps restore the expected balance. With obstructions removed, balancing dampers respond predictably, and measured airflows better match engineering assumptions. That matters for both comfort and durability. Excess indoor humidity, a common side effect of inadequate ventilation, can feed microbial growth on cold duct surfaces, particularly around uninsulated metal in cool spaces. Cleaning is not a cure-all—leaky ducts, crushed flex runs, and poor design still need attention—but it creates a clear path so that fixes like sealing, insulation, and rebalancing produce the intended results. It also protects energy recovery components and filters by keeping upstream debris from loading them prematurely.

When planning improvements, think in sequences:

– Clear the path: clean returns and supplies to lower resistance

– Fix the leaks: seal joints and boots to prevent bypass air

– Set the speed: adjust fan settings to hit ventilation targets

– Verify results: confirm with spot measurements at registers

HVAC efficiency, energy, and comfort gains from clear ductwork

Heating and cooling equipment is only as efficient as the air that passes over its coils and heat exchangers. Dirty or obstructed ducts reduce airflow, and low airflow undermines heat transfer. On cooling calls, insufficient flow can allow the evaporator coil to run too cold, flirting with icing and forcing longer runtimes to meet the thermostat setpoint. On heating calls, it can push temperatures higher at the furnace, triggering safety limits and short cycling. Both scenarios waste energy and wear components faster than necessary. By reducing static pressure and restoring design airflow, duct cleaning can help the equipment operate inside its intended window, which is where efficiency and comfort are strongest.

The energy story is straightforward: when fans work against higher resistance, they draw more power; when airflow is low, compressors and burners run longer. Field studies consistently show that returning airflow to specification can deliver meaningful savings, often in the single-digit to low double-digit range depending on how severe the restriction was. Consider a modest example. If compromised ducts add just 30 minutes of extra runtime per day in peak season and the system averages 1 kilowatt of demand during those periods, that is roughly 15 kilowatt-hours a month saved by removing the bottleneck—before considering secondary gains like fewer defrost events or reduced supplemental heat use.

Efficiency is not only a number on a bill; it is also felt as steadier rooms and quieter operation. Clear ducts let variable-speed fans settle into lower, smoother settings more often, reducing noise while maintaining flow. Even fixed-speed systems benefit as pressure drops, registers deliver a stronger, more consistent stream, and rooms equalize faster after setbacks. Maintenance costs follow a similar pattern. Cleaner ducts help keep coils and blower wheels from loading up as quickly, delaying the need for deep equipment cleanings. Filters last closer to their rated service life because they are not catching a constant trickle of duct-borne debris dislodged at every start-up.

To put these gains into perspective, compare the before and after state:

– Before: elevated static pressure, longer runtimes, uneven rooms, frequent dust plumes

– After: lower static pressure, shorter cycles, balanced rooms, quieter starts

– Side effect: fewer nuisance service calls related to limit trips or coil icing

– Long view: reduced stress on motors and bearings, supporting longer equipment life

Health, cleanliness, and risk reduction: when cleaning matters most

While no single service can guarantee perfect air, removing accumulations from ductwork helps reduce the sources that feed irritation and mess. Dust is a blend of fibers, skin flakes, tracked-in soil, soot, and microscopic fragments from everyday activities. Add pet dander, spilled cereal, or renovation debris, and ducts become a sampler of the building’s past. When the fan starts, some portion of that material can lift, drift into occupied zones, and settle onto surfaces. Regular cleaning reduces that reservoir, which in turn lowers the frequency of dust settling and the chance of odors riding the airstream from one room to another.

There are also specific risk scenarios where cleaning moves from helpful to strongly advisable. If a moisture event has occurred—say, a roof leak above a return chase or prolonged condensation in a cool crawlspace—duct interiors can harbor damp spots that support microbial growth. If pests have nested in or near duct runs, residues and droppings need to be safely removed. After major renovation, fine gypsum dust and sawdust can linger in returns, find their way to coils, and stir up during normal cycles. In any of these cases, professional cleaning with containment and appropriate protective measures is a prudent step in returning the system to a hygienic baseline.

It is also wise to address upstream causes: fix moisture intrusions, improve sealing and insulation around ducts in unconditioned spaces, and use door sweeps or boot gaskets to limit infiltration. Cleaning without correction simply resets the clock. For occupants, the practical benefits of tackling both include fewer visible dust trails around grilles, reduced stale or musty smells after start-up, and more consistent room conditions. Those are tangible quality-of-life improvements that can be noticed without instruments. At the same time, realistic expectations matter. Duct cleaning complements, but does not replace, regular filter changes, source control (like capturing particles at a workshop tool), and adequate ventilation rates.

Common triggers that make cleaning a high priority:

– Water exposure, condensation, or visible staining inside ducts

– Evidence of pests, nesting materials, or unusual odors

– Post-renovation residue after drywall sanding or flooring work

– Persistent dust plumes or streaking around registers and returns

Conclusion and maintenance roadmap for homeowners and facility managers

Professional duct cleaning provides value by restoring clear airflow pathways, reducing the dust reservoir inside the system, and helping equipment operate within its design range. The service is most effective when executed as part of a broader maintenance plan. A thorough visit typically includes a visual or video inspection, system isolation and negative-pressure collection, mechanical agitation along trunks and branches, careful cleaning of registers and boots, and attention to the air handler cabinet. Technicians should protect furnishings, seal access openings afterward, and verify that components such as dampers and sensors are left in their intended positions. When finished, a short report with observations and photos helps you prioritize any follow-up work like sealing, insulation, or balancing.

How often should you schedule it? Frequency depends on use and environment. Homes with shedding pets, frequent cooking, or nearby construction may benefit from shorter intervals, while a lightly used system with strong filtration can go longer. A practical approach is to inspect every one to two years and clean as conditions warrant, targeting a three-to-five-year cadence for typical households and as-needed for commercial spaces based on measured pressure drops and cleanliness. Remember that the goal is prevention: by keeping surfaces clean and resistance low, you avoid the slow creep of inefficiency and stuffiness that is hard to diagnose later.

To make the most of the investment, pair cleaning with simple, repeatable steps:

– Replace filters on schedule and use an appropriate efficiency rating for your system

– Seal obvious duct leaks at joints and boots to cut bypass air and dust draw

– Insulate ducts in unconditioned spaces to prevent condensation on cool surfaces

– Keep returns clear of clutter and avoid locating them near heavy dust sources

For homeowners, the payoff shows up as quieter starts, steadier rooms, and less dusting. For facility managers, it appears in fewer comfort complaints, smoother balancing, and reduced wear on fans and coils. Clean ducts do not solve every air quality or ventilation challenge, but they remove a major variable, making the rest of your strategies work as intended. If indoor air quality, ventilation performance, and HVAC longevity matter to you—and they likely do—put regular professional duct cleaning on the calendar, confirm results after each service, and enjoy the compounding benefits of a system that breathes freely.