Comprehensive Guide to Conducting an Energy Audit

Outline of the article:

– What an energy audit is, why it matters, and how audits are categorized by depth

– Efficiency opportunities across building envelope, HVAC, lighting, controls, and plug/process loads

– Sustainability gains, emissions metrics, and electrification pathways

– Cost savings, payback horizons, and funding options

– Turning audit findings into an actionable plan with tracking and verification

Introduction: Why Energy Audits Matter

An energy audit is a structured look at how a building uses energy, where it is wasted, and which improvements deliver reliable savings. Buildings account for a significant portion of global energy use and energy-related emissions, so reducing consumption at the source—your home or facility—has real environmental and financial weight. A well-run audit identifies how heat moves through walls and windows, how air sneaks in or out, how equipment performs versus what it promised on paper, and how occupant habits shape peaks and lulls in demand. Instead of guessing, you gather data, compare performance against norms, and prioritize fixes that match your goals, budget, and timing.

Audits generally fall into tiers. A walkthrough or preliminary audit uses utility bills, visual inspection, and simple measurements to flag obvious issues—drafty doors, outdated lamps, or equipment running after hours. A detailed or targeted audit adds metering, logging, and diagnostic tests such as blower-door measurements or thermography, quantifying losses and expected impacts. An investment-grade audit goes further, building models, validating baseline assumptions, and supporting financing decisions with dependable cost and savings estimates. Each step increases certainty and helps you avoid surprises, especially when planning capital projects.

To make the most of the process, frame the audit around clear objectives. For a homeowner, the aim might be comfort and lower bills without major disruption. For a facility manager, it might be reducing operating costs, preparing for code changes, or meeting organizational climate commitments. Typical savings from a solid package of measures can range from about 10 to 30 percent of annual energy use, with quicker wins from behavior and controls, and deeper cuts from envelope and equipment upgrades. Along the way, a good audit also reveals co-benefits: quieter spaces, steadier temperatures, extended equipment life, and improved indoor air quality. Think of it as tuning a musical instrument—you’ll hear the difference every day.

Efficiency: Mapping Loads, Plugging Leaks, and Optimizing Systems

Efficiency gains start with a map of where energy goes. Examine your utility bills for at least a year to understand seasonal swings, then match them to use categories: space conditioning, water heating, lighting, appliances, and any special process loads. In many homes, heating and cooling can account for roughly 40 to 60 percent of energy use; in commercial spaces, ventilation fans, pumps, and internal loads from lighting and electronics add up quickly. A short list of tools can sharpen the picture: an infrared camera highlights insulation voids and thermal bridges, a data logger captures temperature and humidity trends, and a smart plug meter reveals which devices sip power all night.

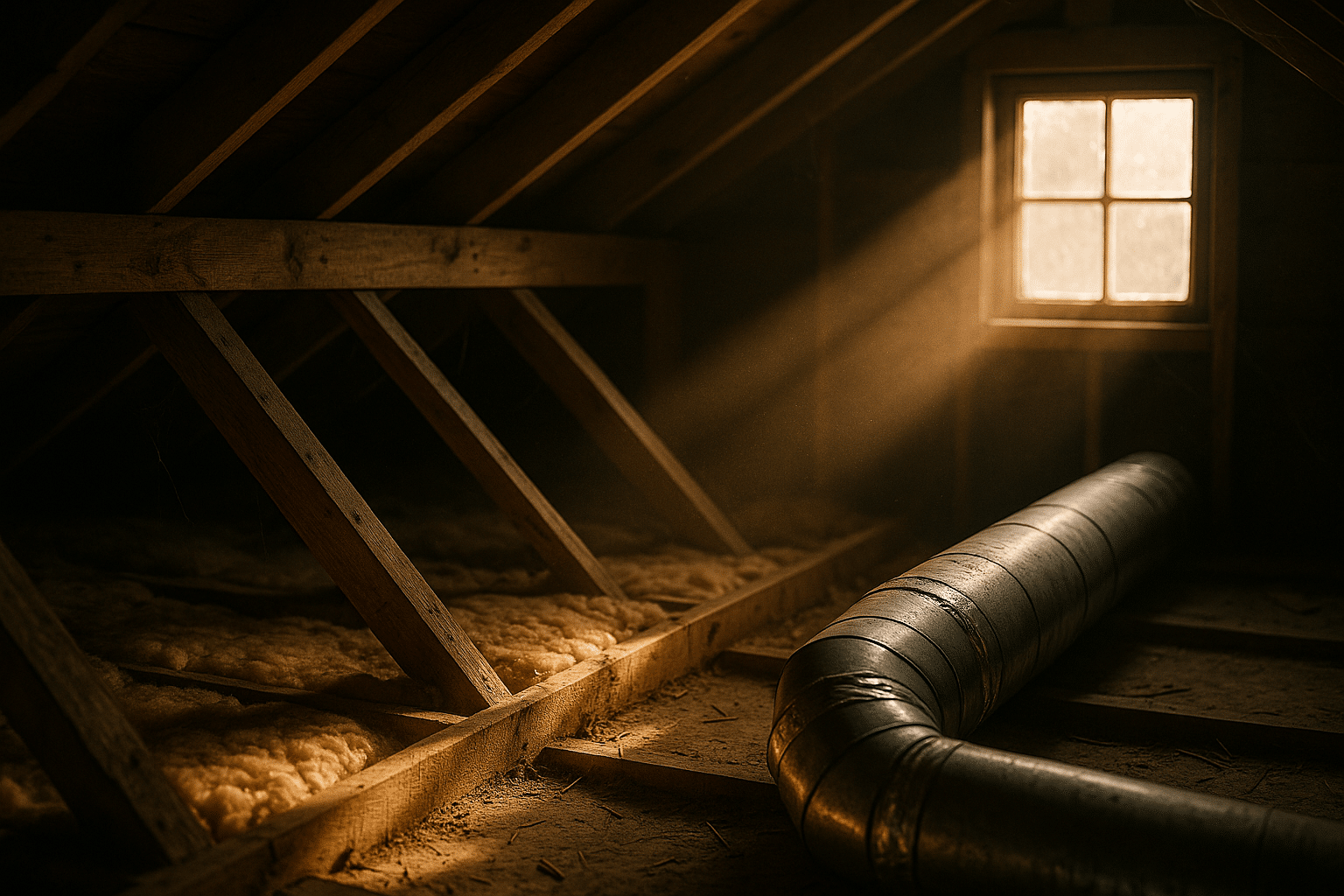

Begin at the envelope, because keeping conditioned air where you want it reduces everything downstream. Air sealing gaps at attic penetrations, rim joists, and around windows can significantly cut infiltration; even modest work often yields noticeable comfort gains. Insulation levels matter, but continuity matters more—bridges at framing, recessed lights, and poorly fitted hatches undermine thick batts. High-performance windows help, yet sealing and shading can rival their impact at far lower cost. Compared to reactive fixes, a systematic approach—test, seal, insulate—delivers steadier indoor temperatures and reduces the burden on mechanical systems.

Next, scrutinize HVAC. Tune-ups, correct refrigerant charge, and proper airflow can restore efficiency to nameplate levels. Smart thermostats and lockable setpoints reduce unnecessary runtime, and zoning or occupancy-based control trims energy in rarely used spaces. Variable-speed drives on fans and pumps can reduce motor energy use substantially under partial loads. For water heating, lowering setpoints, adding pipe insulation, and fixing recirculation schedules can curb waste. Lighting remains a straightforward upgrade: modern lamps use far less electricity than older technologies and last longer, easing maintenance. Within offices and classrooms, daylighting, occupancy sensors, and task lighting can reduce overhead lighting hours without sacrificing visibility.

Plug and process loads deserve equal attention. Office equipment left active after hours can quietly consume a meaningful share of energy. Strategies include timed shutoffs, advanced power strips, and default sleep settings. In kitchens or workshops, right-sizing equipment and regular maintenance (clean coils, aligned belts, lubricated bearings) bring immediate returns. To summarize practical priorities:

– Start with envelope tests and air sealing, then improve insulation where continuity is weak

– Restore HVAC performance through tune-ups and controls before considering replacement

– Upgrade lighting and manage controls to cut runtime while preserving comfort and safety

– Tackle plug loads with schedules, smart controls, and equipment settings

Sustainability: Cutting Emissions and Conserving Resources

Sustainability in an energy audit goes beyond kilowatt-hours to include carbon, water, air quality, and resilience. A clear metric is emissions intensity—the kilograms of carbon dioxide equivalent per unit of electricity or fuel consumed. This varies by region and energy mix, so an audit should note local grid factors and fuel types. Electrification of end uses, especially space and water heating, can unlock sizable emissions reductions when paired with an increasingly clean grid. Combined with envelope improvements and smart controls, electrification shifts energy from combustion on-site to efficient, controllable electric systems.

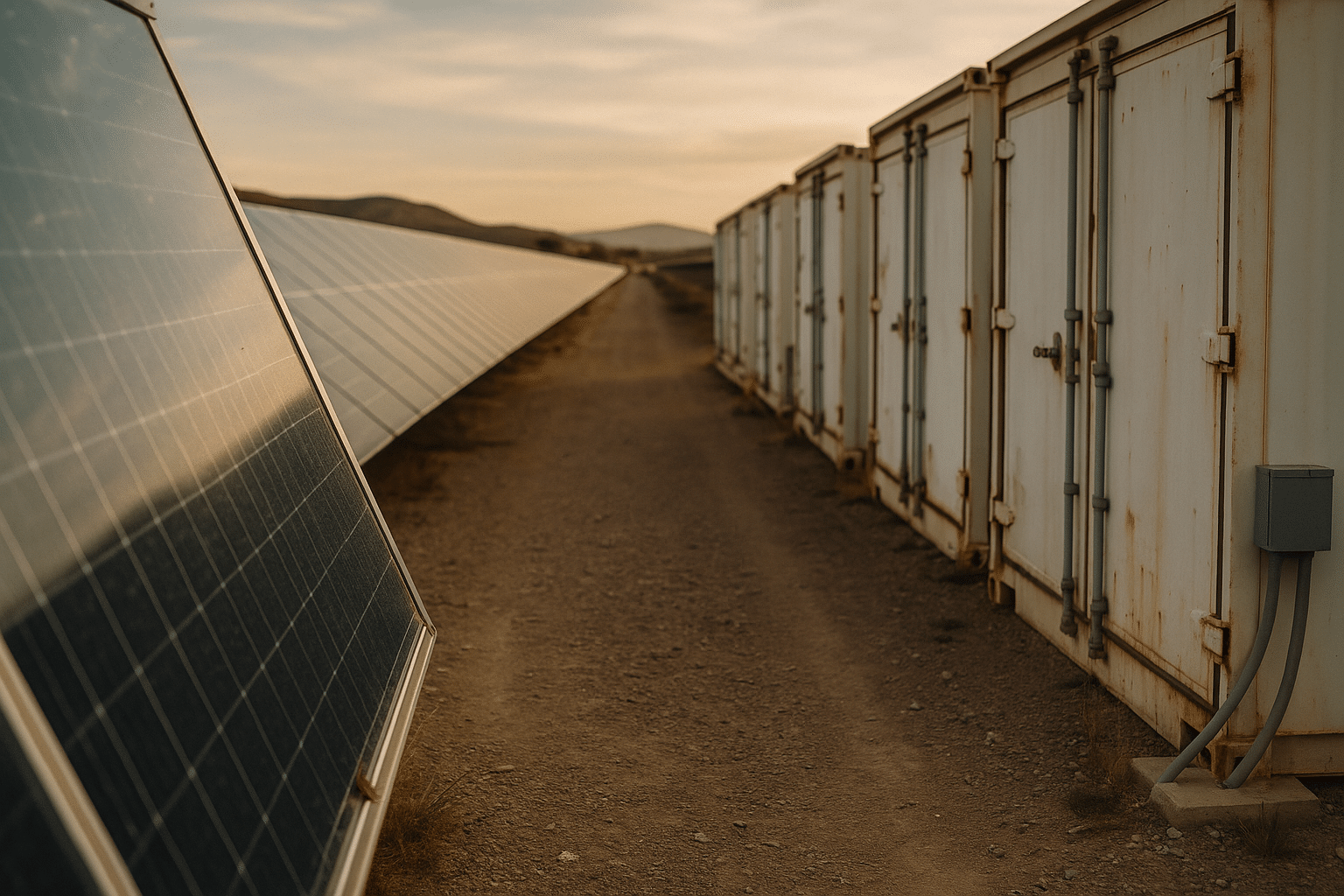

On-site renewables complement reductions from efficiency. Rooftop solar, shared community arrays, or small-scale wind (where feasible) can offset a significant slice of annual use. Storage adds flexibility, allowing you to shave peaks and ride out brief outages. Even without generation, demand flexibility—pre-cooling before peak hours, staggering high-load tasks, or leveraging thermal storage in well-insulated masses—lowers stress on the grid and reduces emissions during high-pollution periods. Water efficiency matters, too: low-flow fixtures and leak detection reduce hot-water demand, decreasing both water and energy use in tandem.

Materials and refrigerants carry environmental footprints that audits should recognize. When replacing systems, favor equipment with lower global warming potential refrigerants and ensure responsible end-of-life recovery. In the building fabric, targeted air sealing and cellulose or mineral-based insulation can offer performance with comparatively modest embodied carbon, especially when reusing existing assemblies. Ventilation upgrades that incorporate balanced airflow and high-efficiency heat recovery preserve indoor air quality while minimizing heating and cooling penalties, aligning occupant health with energy goals.

Verification keeps sustainability claims honest. Track energy use intensity (for example, kWh per square meter per year), correlate with weather via degree days, and monitor carbon intensity to understand how improvements perform across seasons. Simple dashboards or periodic reviews can highlight drift in schedules or setpoints, prompting quick corrections. A few focus points help maintain momentum:

– Prioritize measures that reduce both energy and peak demand to cut emissions and operational costs

– Combine envelope improvements with electrification for compounding benefits over time

– Monitor indoor air quality to ensure comfort and health remain central as systems tighten and controls become more precise

Cost Savings: From Quick Wins to Strategic Investments

Cost savings from an energy audit arrive on different timelines. Quick wins include schedule fixes, thermostat calibration, and LED lighting retrofits, which often pay back in months. Moderate investments—air sealing, insulation top-ups, and advanced controls—tend to pay back over a few heating or cooling seasons while delivering comfort and resilience. Larger projects, such as high-efficiency HVAC replacements or comprehensive window upgrades, demand more capital and evaluation. An audit should lay out these tiers clearly, with expected savings ranges, installed costs, and simple paybacks, while also discussing longer-horizon metrics such as net present value and internal rate of return.

Understanding your utility tariff is essential. Time-of-use rates reward shifting consumption to off-peak hours, and demand charges can dominate bills for commercial customers. By aligning controls, sequencing equipment, and smoothing startups, you can reduce coincident peaks that drive high charges. Submetering specific loads—such as a server room or kitchen line—reveals patterns and opportunities not visible in whole-building bills. For many users, curbing a few predictable spikes can rival the savings from hardware upgrades.

Maintenance is a cost-saving strategy in its own right. Clean filters, tuned burners, tight belts, and calibrated sensors restore efficiency that drifted away over time. Fixing economizer controls or repairing a faulty damper can save more than it costs within a single season. On the occupant side, training and feedback loops keep behaviors aligned with goals: lights off in sunlit rooms, doors closed during extreme weather, and equipment shut down at day’s end. Because people set schedules and respond to comfort, engaging them multiplies the value of technical measures.

Financing options can make larger projects feasible without straining budgets. Some regions offer rebates for insulation, controls, or high-efficiency equipment, and various performance-based programs reward verified savings over time. On-bill repayment, property-assessed financing, or service contracts that tie compensation to measured results can align incentives and reduce risk. A practical decision framework might include:

– Implement no- and low-cost measures immediately to capture fast savings

– Bundle medium-cost work with maintenance or minor renovations to reduce disruption and labor costs

– Use detailed audits to vet major projects, selecting those with strong lifecycle economics and manageable risk

– Plan measurement and verification from the start to ensure savings persist and qualify for incentives

Conclusion: Turning an Audit into Action

An energy audit only pays off when insights become steps on a calendar. Begin by prioritizing measures with clear savings and minimal disruption, such as schedules, setpoints, and sealing obvious leaks. Line up moderate upgrades—insulation improvements, lighting controls, and ventilation balancing—so they coincide with seasonal breaks or planned maintenance. For bigger changes, such as replacing aging HVAC or electrifying water heating, use the audit’s cost and savings estimates to build a multi‑year plan that matches your cash flow and comfort needs. Keep the plan visible, and revisit it at least annually to adjust for energy prices, usage patterns, or new incentives.

Homeowners and small business teams can split tasks effectively. Assign someone to gather bills, someone to coordinate contractors, and someone to track results against the baseline. A simple scorecard helps: monthly energy use per square meter, peak demand notes if applicable, indoor temperature stability, and any comfort complaints. When the numbers drift, the checklist points to likely culprits—changed hours, a stuck damper, or a forgotten schedule override. This practical rhythm turns the audit from a one-time report into an ongoing practice.

Finally, celebrate the non-monetary wins. Quieter rooms, steadier temperatures, and cleaner air matter each day, while trimmed emissions support local air quality and broader climate goals. As improvements stack, your building becomes easier to operate and more adaptable to weather extremes or price swings. If you started this journey to cut bills, you’ll likely find that efficiency, sustainability, and comfort reinforce one another. Keep measuring, keep tuning, and share results with occupants or stakeholders—the momentum you build will sustain the savings you’ve unlocked.